Negative

impacts of variable renewable energy (Wind and Solar) JR173

Introduction

The wind and sun may be free, green, renewable and

sustainable. But the energy, land and materials required to harness and

utilize that energy certainly are not. Renewable power

technologies such as wind and solar

are becoming economically competitive with fossil fuels. As ecological need and

economic reality converge, renewables are going to make up an increasingly

large percentage of the world’s power supply. It’s a necessary technological

transition. But at the same time, renewables have a downside that needs to be

addressed:

Life of plants

Wind

and solar systems also break down faster and must be replaced earlier and more

often than coal, gas or nuclear power plants—which have operational life spans

of 30-50 years, and generate power about 95% of the time. Wind energy proponents

claim turbines last half that long: 20-25 years. They don’t.

A 2018 UK analysis

of 3,000 onshore wind turbines found that they generate electricity efficiently

for just 12-15 years (and maybe 25-30% of the time)—generating more than twice

as much electricity, in their first year than when they are barely 15 years

old. So wind turbine raw materials depletion and land use impacts are far

higher than advocates have admitted. These realities are no better for solar

installations.

All

of this also means the cost of wind and solar electricity is far higher than

their advocates admit

.

Rare-earth, metals.

To read more about rare earth metals : Negative Impacts of Renewable Energy.docx , https://javedrashid.blogspot.com/2018/10/rare-earth-metals.html

Rare-earth elements are used in virtually all electronics.

This includes solar panels, which require rare earth metals such as yttrium or

europium, and wind power, which uses vast quantities of neodymium in the

magnets that help convert wind energy to electricity.

Rare earth elements

are actually fairly abundant in the Earth’s crust. But these metals are

typically found in extremely low concentrations. That means a lot of

destructive mining for minimal effect. Rare earth mining produces large

quantities of contaminated mine waste, creating a disposal problem.

Additionally, many of

the most productive rare earth mines are in countries with weak environmental

regulations. Political instability and national security concerns provide

further risks to long-term supply. Accordingly, Smith writes, recycling these

elements is big business, employing thousands of mostly unskilled workers

worldwide. Formal, supervised recycling processes are needed to safely dismantle

and recycle the materials, in contrast to the informal recycling systems that

are currently in place. These informal systems are cheaper but may expose

workers to health risks. Even so, the formal and informal economies often work

in tandem. Smith suggests charging a fee upfront so electronics producers and

consumers have to pay for the costs to properly recycle these products. The

most efficient solution would be to reuse electronics when possible. One

positive trend is that reuse is becoming more and more common. Smith suggests a

global collection system to maximize reuse and keep electronic waste away from smugglers

and illegal disposal.

Another idea

suggested by scholars Robert U. Ayres and Laura Talens Peiró is maximizing “material efficiency” for rare earths and other crucial

materials. Currently, when high grade ore is mined, lower

quality ores or unwanted side materials, the mining equivalent of fisheries’ by

catch, are excavated but not used. In addition to recycling, finding uses for

these mining byproducts could potentially reduce waste in the electronic and

renewable energy sector. One drawback is that some of these lower-grade

materials are energy intensive to collect, given the low yield.

In the short term,

the risks of mining rare earth elements do not outweigh the benefits of

renewable power, but improvements are needed. And when it comes to each

individual’s impact, forgoing that latest smart phone upgrade may just be the

best thing you can do.

Impact of Wind turbine vibrations on

Ground water and Shale

Ground

water contamination has been reported from Canada, from areas where the bedrock

is comprised of shale,. This needs to be investigated as in Pakistan we have

areas where wind is feasible and the bedrock or geology is shale based. Large

wind turbines are getting larger and therefore require a large pylon to support

the machine. This requires to pile-drive a massive steel beams into the

bedrock. The problem is that the bedrock may be made of shale and is known to

contain uranium and arsenic. Vibration from the pile-driving breaks up this

toxic shale below the groundwater and contaminates it. Area residents can’t

drink, bathe, or wash their clothes because of this. Water wells are being

poisoned . Construction of wind turbines

continues even though scientific tests at several farms show that well water

has been contaminated.

Canadian users of ground

water, attribute contamination of ground water to the wind

turbines being built nearby and the companies developing them. A large number of local rural residents who

believe the problems with their well water owe to the interaction between local

wind farm development and the area’s unique geology. The sedimentary bedrock —

dark in color and fine-grained — lurks beneath most of Chatham-Kent. It’s known

to contain sulphur, carbon, and toxic heavy metals. A resident says that his

well was drilled by his father half a century ago and had always run clear —

until sediment clogged it last October. Now, the water is the color of tea and

when poured and small particles sink to the bottom of a glass.

Ensuing government research debunked some of

the claims. A 2014 health federal health study, for instance, showed that “annoyance” was the

sole condition found to increase as levels of wind turbine noise increased.

(The report did note that community annoyance was statistically related to

health effects such as migraines, blood pressure changes, tinnitus, and

stress.). But events in Chatham-Kent raise the possibility that the massive

wind catchers pose unique and under-considered risks to the region’s

environment, and the health and safety of its residents.

Spokesman for Water Wells First and an area

farmer says the concern is that vibrations — either from pile driving

during the construction phase or, eventually, the everyday operations of the

turbines — might disturb the fragile Kettle Point black shale bedrock and

contaminate the ancient aquifer that serves as the local source of well water.

The worry was justified: It is well established that vibrations from pile driving can damage nearby

structures. As for ordinary turbine operations, one recent Canadian study

found a relationship between the vibrations and ground material within 100

meters of the structure.

Moreover, Water Wells First contends that the

company and ministry didn’t take the special characteristics of the local

geology into account. Residents realized their worst fears as the project began

the construction phase last summer. Nineteen wells began to experience sediment

problems, nearly a third of the 64 wells that the group members had tested at

their own expense. Bill Clarke, a hydro geologist for Water Wells First who

gathered and analyzed the samples, says follow-up testing showed the affected

wells experienced changes in water turbidity, amount of particles, color, and

rate of flow. While he says some of the changes were marginal, others were

alarming. In one instance, the black shale particle count jumped from 47

particles per milliliter to 681,939 — with nearly half of the particles being

as tiny as those found in cigarette smoke.

Tiny particles are potentially dangerous

because they can be too small to settle to the bottom of a well, nor can they

be controlled using conventional water filtration systems. A medical geologist

based in Ingersoll, says the acidic atmosphere in the stomach can break down

the binding between a clay-based shale particle and any heavy metals attached,

allowing the metals to settle in other areas of the body rather than to pass

through our digestive system

Wade

said turbines can be retrofitted to dampen vibrations and alternative anchoring

systems are available, but those would cost more. The water table is fragile in

Dover, part of a geological area stretching from Lake Huron to Chatham-Kent.

There are just 50 to 70 feet of overburden in most places covering black shale

bedrock.

Jakubec

and Stainton said there are studies from Scotland and Italy that have

identified seismic coupling. Jakubec, a green energy researcher, said impacts

tend to be felt from 1.5 to five kilometers away from turbine locations. Geological

engineer Maurice Dusseault wasn’t surprised to hear that Chatham-Kent water

wells were contaminated in the wake of pile driving for wind turbines.“Pile

driving emits a lot of low-frequency energy, and it is not at all surprising to

me that there could be related groundwater effects. The concept of

large-amplitude, low frequency excitation as an aid to liquid flow is reasonably

well-known,” the University of Waterloo professor said. “Low frequency

deformation waves are absolutely known to lead to fluctuation in ground water

levels as well as changes in the particulate count in shallow groundwater

wells.”

In

addition, Dusseault said affected residents were well-advised in having their

wells baseline tested prior to construction last summer. It’s the type of

evaluation he recommends. Before and after tests sent by the Water Wells First

citizens’ group to RTI Laboratories in Michigan show an exponential increase

[in] turbidity among the 14 affected wells, including [a] large proportion that

can be attributed to Kettle [Point] black shale particles

that are known to contain heavy metals, including uranium, arsenic and lead.

That’s

not the conclusion reached by the Ministry of the Environment and Climate

Change, as outlined in letters recently sent to affected well owners living

near the North Kent One project in the northern part of the Municipality of

Chatham-Kent. Whilst there’s been an admission that wells have indeed been

contaminated. That contamination can

only be attributed to “unidentified factors.” Pile-driving activities

associated with wind turbine development are not to blame, the MOECC maintains.

The

MOECC, in coming to its conclusion, relied upon the vibration evaluations

prepared for the developers Samsung and Pattern Energy, by Golder Associates

Limited. Golder measured changes to particle velocity as a measure of vibration

intensity created by pile driving.

The concerns have been dismissed by Chatham-Kent’s Medical Officer

of Health who concluded that there is no health risk from undisclosed particles

in water when no bacteria are present. Jakubec, however, said there are at

least two potential pathways through which the heavy metals in black shale

particles can enter the human body.

The issue is discussed, in detail, at: https://javedrashid.blogspot.com/2018/08/impact-of-wind-turbine-vibrations-on.html

Environmental impacts of Wind Energy

Despite its vast wind potential and benefits,

there are a variety of environmental impacts associated with wind power

generation that should be recognized and mitigated.

Land Use

The land use impact of

wind power facilities varies substantially depending on the site: wind turbines

placed in flat areas typically use more land than those located in hilly areas.

However, wind turbines do not occupy all of this land; they must be spaced

approximately 5 to 10 rotor diameters apart (a rotor diameter is the diameter

of the wind turbine blades). Thus, the turbines themselves and the surrounding

infrastructure (including roads and transmission lines) occupy a small portion

of the total area of a wind facility.

A survey by the

National Renewable Energy Laboratory of large wind facilities in the United

States found that they use between 30 and 141 acres per megawatt of power

output capacity (a typical new utility-scale wind turbine is about 2

megawatts). However, less than 1 acre per megawatt is disturbed permanently and

less than 3.5 acres per megawatt are disturbed temporarily during construction.

The remainder of the land can be used for a variety of other productive

purposes, including livestock grazing, agriculture, highways, and hiking trails

. Alternatively, wind facilities can be sited on brownfields (abandoned or

underused industrial land) or other commercial and industrial locations, which

significantly reduces concerns about land use

(Hybrid solar and wind farms save land and have other benefits, read more at https://javedrashid.blogspot.com/2018/10/hybrid-solar-wind-power-plants.html)

Offshore wind facilities require larger amounts of space because

the turbines and blades are bigger than their land-based counterparts.

Depending on their location, such offshore installations may compete with a

variety of other ocean activities, such as fishing, recreational activities,

sand and gravel extraction, oil and gas extraction, navigation, and

aquaculture. Employing best practices in planning and siting can help minimize

potential land use impacts of offshore and land-based wind projects

Wildlife and Habitat

The impact of wind turbines on

wildlife, most notably on birds and bats, has been widely document and studied.

A recent National Wind Coordinating Committee (NWCC) review of peer-reviewed

research found evidence of bird and bat deaths from collisions with wind

turbines and due to changes in air pressure caused by the spinning turbines, as

well as from habitat disruption. The NWCC concluded that these impacts are

relatively low and do not pose a threat to species populations

Additionally, research into wildlife

behavior and advances in wind turbine technology have helped to reduce bird and

bat deaths. For example, wildlife biologists have found that bats are most

active when wind speeds are low. Using this information, the Bats and Wind

Energy Cooperative concluded that keeping wind turbines motionless during times

of low wind speeds could reduce bat deaths by more than half without

significantly affecting power production. Other wildlife impacts can be

mitigated through better siting of wind turbines. The U.S. Fish and Wildlife

Services has played a leadership role in this effort by convening an advisory

group including representatives from industry, state and tribal governments,

and nonprofit organizations that made comprehensive recommendations on appropriate

wind farm siting and best management practices

Offshore wind turbines can have similar

impacts on marine birds, but as with onshore wind turbines, the bird deaths

associated with offshore wind are minimal. Wind farms located offshore will

also impact fish and other marine wildlife. Some studies suggest that turbines

may actually increase fish populations by acting as artificial reefs. The

impact will vary from site to site, and therefore proper research and

monitoring systems are needed for each offshore wind facility

Public Health and

Community

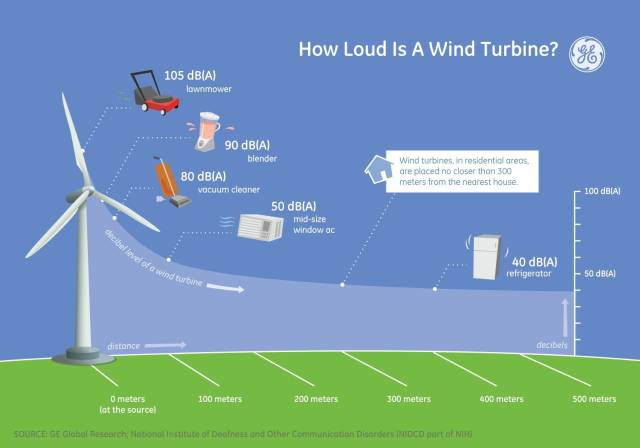

Sound and visual impact are the two

main public health and community concerns associated with operating wind

turbines. Most of the sound generated by wind turbines is aerodynamic, caused

by the movement of turbine blades through the air. There is also mechanical

sound generated by the turbine itself. Overall sound levels depend on turbine

design and wind speed.

Some people living close to wind

facilities have complained about sound and vibration issues, but industry and

government-sponsored studies in Canada and Australia have found that these

issues do not adversely impact public health . However, it is important for

wind turbine developers to take these community concerns seriously by following

“good neighbor” best practices for siting turbines and initiating open dialogue

with affected community members. Additionally, technological advances, such as

minimizing blade surface imperfections and using sound-absorbent materials can

reduce wind turbine noise .

Under certain lighting conditions,

wind turbines can create an effect known as shadow flicker. This annoyance can

be minimized with careful siting, planting trees or installing window awnings,

or curtailing wind turbine operations when certain lighting conditions exist .

The Federal Aviation Administration

(FAA) requires that large wind turbines, like all structures over 200 feet

high, have white or red lights for aviation safety. However, the FAA recently

determined that as long as there are no gaps in lighting greater than a

half-mile, it is not necessary to light each tower in a multi-turbine wind

project. Daytime lighting is unnecessary as long as the turbines are painted

white.

When it comes to aesthetics, wind turbines can

elicit strong reactions. To some people, they are graceful sculptures; to

others, they are eyesores that compromise the natural landscape. Whether a

community is willing to accept an altered skyline in return for cleaner power

should be decided in an open public dialogue.

Life-Cycle Global Warming

Emissions

While there are no global warming emissions

associated with operating wind turbines, there are emissions associated with

other stages of a wind turbine’s life-cycle, including materials production,

materials transportation, on-site construction and assembly, operation and

maintenance, and decommissioning and dismantlement.

Estimates of total global warming

emissions depend on a number of factors, including wind speed, percent of time

the wind is blowing, and the material composition of the wind turbine . Most

estimates of wind turbine life-cycle global warming emissions are between 0.02

and 0.04 pounds of carbon dioxide equivalent per kilowatt-hour. To put this

into context, estimates of life-cycle global warming emissions for natural gas

generated electricity are between 0.6 and 2 pounds of carbon dioxide equivalent

per kilowatt-hour and estimates for coal-generated electricity are 1.4 and 3.6

pounds of carbon dioxide equivalent per kilowatt-hour.

Environmental Impacts of Solar

Energy

The potential environmental impacts associated with solar

power are : land use ; habitat

loss; water use; and the use of hazardous materials in manufacturing , these

can vary greatly depending on the technology, which includes two broad

categories: photovoltaic (PV) solar

cells or concentrating solar

thermal plants The scale of the system — ranging from small, distributed rooftop PV

arrays to large utility-scale PV and CSP projects — also plays a significant

role in the level of environmental impact.

Land Use

Depending

on their location, larger utility-scale solar facilities can raise concerns

about land degradation and habitat loss. Total land area requirements vary

depending on the technology, the topography of the site, and the intensity of

the solar resource. Estimates for utility-scale PV systems range from 3.5 to 10

acres per megawatt, while estimates for CSP facilities are between 4 and 16.5

acres per megawatt.

Unlike wind facilities, there is

less opportunity for solar projects to share land with agricultural uses.

However, land impacts from utility-scale solar systems can be minimized by

siting them at lower-quality locations such as brownfields, abandoned mining

land, or existing transportation and transmission corridors. Smaller scale solar

PV arrays, which can be built on homes or commercial buildings, also have

minimal land use impact.

Water Use

Solar PV cells do not use water for

generating electricity. However, as in all manufacturing processes, some water

is used to manufacture solar PV components. Concentrating

solar thermal plants (CSP), like all thermal electric plants, require water for

cooling. Water use depends on the plant design, plant location, and the type of

cooling system.

CSP plants that use

wet-recirculating technology with cooling towers withdraw between 600 and 650

gallons of water per megawatt-hour of electricity produced. CSP plants with

once-through cooling technology have higher levels of water withdrawal, but

lower total water consumption (because water is not lost as steam). Dry-cooling

technology can reduce water use at CSP plants by approximately 90 percent .

However, the tradeoffs to these water savings are higher costs and lower

efficiencies. In addition, dry-cooling technology is significantly less effective

at temperatures above 100 degrees Fahrenheit.

Many of the regions in the World that

have the highest potential for solar energy also tend to be those with the

driest climates, so careful consideration of these water tradeoffs is essential

Hazardous Materials

The PV cell

manufacturing process includes a number of hazardous materials, most of which

are used to clean and purify the semiconductor surface. These chemicals,

similar to those used in the general semiconductor industry, include

hydrochloric acid, sulfuric acid, nitric acid, hydrogen fluoride,

1,1,1-trichloroethane, and acetone. The amount and type of chemicals used

depends on the type of cell, the amount of cleaning that is needed, and the

size of silicon wafer. Workers also face risks associated with inhaling silicon

dust.

Thin-film PV cells

contain a number of more toxic materials than those used in traditional silicon

photovoltaic cells, including gallium arsenide,

copper-indium-gallium-diselenide, and cadmium-telluride. If not handled and disposed

of properly, these materials could pose serious environmental or public health

threats. However, manufacturers have a strong financial incentive to ensure

that these highly valuable and often rare materials are recycled rather than

thrown away.

Life-Cycle Global Warming

Emissions

While

there are no global warming emissions associated with generating electricity

from solar energy, there are emissions associated with other stages of the

solar life-cycle, including manufacturing, materials transportation,

installation, maintenance, and decommissioning and dismantlement. Most

estimates of life-cycle emissions for photovoltaic systems are between 0.07 and

0.18 pounds of carbon dioxide equivalent per kilowatt-hour.

Most estimates for

concentrating solar power range from 0.08 to 0.2 pounds of carbon dioxide

equivalent per kilowatt-hour. In both cases, this is far less than the

lifecycle emission rates for natural gas (0.6-2 lbs of CO2E/kWh) and coal

(1.4-3.6 lbs of CO2E/kWh)

Agriculture

and Solar Cells; Jan., 23, 2020: It’s increasingly been suggested

that solar panels could be used on agricultural fields, producing clean

electricity while maintaining agricultural fields. Mint plants have been analyzed

after having grown on contaminated soil samples. Image credits: Fujian

Agriculture and Forestry University.

Perovskite cells have become some of the most efficient and

productive types of solar cells. Their efficiency can be well over 20% (long

considered to be a landmark in solar energy),

and they can be built from relatively low-cost materials — which means that in

the long run, the produced electricity can be quite cheap. They’re also the fastest-advancing

solar technology, raising even more hopes about their potential.. But

there are some issues to be considered, especially when it comes to lead. The

most commonly studied perovskite absorber is something called methylammonium

lead trihalide — a fiendishly complex substance which can leak lead into the

environment. In fact, all perovskite cells contain methylammonium ions

surrounded by heavy metal atoms. Most commonly, these metal atoms are lead. If

some of this lead does reach the ground, researchers found, it can be easily

absorbed by plants — even more easily easier than lead from other sources.

To test this, Prof. Antonio Abate at the Helmholtz-Zentrum Berlin

and colleagues from Germany, Italy, and China, set up an experimental design.

They contaminated soil samples with lead from either perovskite solar cells or

other lead sources and then cultivated different plants (mint, chili, and

cabbage). After allowing the plants to grow and develop naturally, they

analyzed how much lead could be found in the plant body and leaf.

Surprisingly, the lead from perovskites was 10 times more

bioavailable than other sources of lead contamination — so if any perovskite

lead reaches the soil, it is very likely to be accumulated in plants. Similar

trends were observed when the lead was replaced with tin.

Needless to say, lead is toxic and should not reach the food chain

in any form. But the scale of the problem also warrants some clarification. A

square meter perovskite solar module contains a total of only 0.8 grams of lead

— which is very little compared to other technical sources of lead, such as

batteries. Furthermore, it’s unlikely

that all the lead content would leak into the environment. Nevertheless, it’s a

problem that warrants further investigation, says Professor Christos Markides,

Head of the Clean Energy Processes at Imperial College London, who was not

involved with the study.

“This is an interesting study concerning the environmental

impact of lead in perovskite solar cells, a photovoltaic technology that has

attracted significant attention recently owing to its excellent performance and

promise of lower cost compared to conventional and other alternatives. It is of

note because it explores the impact on plants of the use of lead in such solar

cells and provides evidence that this is something that should be considered

with great care,” Markides explains.

“Concerns relating to the

widespread deployment of lead-based perovskite solar cells have been raised for

some time, given that these toxic materials are soluble in water, so

contamination can lead to environmental but also health issues once they enter

the food chain.”

In addition, there are important limitations to this study. We

don’t really know how much lead actually leaks from these cells, and how it is

absorbed by plants — particularly plants other than the ones trialed here. So

this study shouldn’t be interpreted as “solar panels leak a lot of lead into

plants”.

Andrew Meharg, Professor of Biology at Queen’s University Belfast,

also highlighted the study’s limitations: while this does pinpoint a reason for

further study to better understand the leakage and absorption of perovskite

lead, it is very unlikely that this poses a major environmental problem.

“Lead contamination of soils is multiple and extensive, and in

cases extreme, globally, from a wide range of industrial and domestic

activities, yet lead in crops is not really a concern due to lead’s poor

mobility in soils, its limited uptake by and restricted translocation within

plants.”

“The lead from the

peroskovite lead is only 0.1% of panels, and only doubles in the edible parts

(leaves) of one plant (mint), tested on one soil. The break-up and leaching

scenarios to soils of solar panels needs investigated, this was not conducted

here, To state that all lead in solar panels should be replaced, with another

toxic and problematic element tin, from such limited findings is not warranted

without further extensive testing in a range of actual soils that have been

contaminated in situ by disused solar panels.”

https://www.zmescience.com/science/solar-panels-lead-plants-21012020/

Drawbacks of VRE: Jun., 12, 2020: The film starts by

highlighting the primary limitation of wind and solar power: They’re weather

dependent and sometimes produce no electricity. Consequently, these

intermittent sources need to be backed up by something more reliable, and, as

the filmmakers found, those reliable electricity sources are often fossil

fuels. In addition to sometimes not showing up for work, wind and solar plants

require nearly 100 times more land to generate the same

amount of electricity as a natural gas plant. The film

illustrates this in detail, showing a football-field-sized solar array only

capable of powering just 10 homes in a Michigan town. At one point, the site

developer notes that to power the whole town, it would take a solar array so

large it would require 15-square miles.

The

alternative to relying on fossil fuels for backup is large-scale lithium

battery storage. The film notes, however, that these batteries are prohibitively

expensive, and the current world supply of energy battery storage

can hold just one tenth of one percent of global energy usage.

These

obstacles are enough that, after several decades and half a trillion dollars of

investment

(even more globally), wind and solar combined generate just 9 percentof

America’s electricity and less than 4

percent of its energy.

But even

these challenges deal only with fully functional green technologies. The film

shows that creating wind turbines, solar panels and batteries relies on a mining and

manufacturing process so intensive that one wonders if saving the

planet really is the goal. The production of each of these technologies depends

on the very fossil fuels they’re attempting to replace and creates

indispensable toxic waste in the process. The film also notes the frequent

large-scale habitat

destruction that accompanies green energy installations,

underscoring the inescapable fact that every energy

source has an environmental impact.

Further,

wind turbines and solar panels have lifespans of roughly 20 years, which means

this process must be repeated. This lifespan is less than half the lifespan of

any traditional plant, adding to the land use disparity. For instance, natural

gas plants can last

40 years, and nuclear plants between

60-80 years.

All

these challenges underscore the point made by environmental scholar Richard

York interviewed in the film: Contrary to popular belief, green energy does a poor job displacing fossil

fuels. It takes “between four and thirteen units of non-fossil energy to displace

one unit of fossil energy.”

This

isn’t to say, though, that the pursuit of green energy is futile. When used in

moderation, wind and solar power can relieve pressure on the grid by providing

low-cost electricity. As the film notes, however, problems arise when green

energy integration is stretched beyond its

useful limits. It doesn’t matter how cheap green energy gets if it

can’t provide electricity when you need it.

While

the film indulges in overpopulation

theories and anti-capitalist rhetoric typical of Moore’s films, it nonetheless

is an important contribution to the green energy discussion. The general public

has largely been shielded from green energy’s intermittency, scale, land use

and lifespan barriers that energy analysts have written about for years. By

introducing these matters to a wider audience, Moore has reminded us that while

green energy certainly has its place, it also has its limits.

No comments:

Post a Comment